Optical fiber-to-the-business deployment is accelerating globally to support increasing internet speeds of up to 1 Gigabit per second, and 10 Gigabit speeds that are already available in some regions. Service providers are responding by installing optical fiber both to and deep inside buildings to the living unit.

The Solutions in this 64-page guide can help reduce both first and life cycle costs of optical fiber deployments to residential and business customers.

Solutions for both Greenfield installation during building construction and Brownfield installation in existing buildings are included. Scalable and optimized to fit a broad range of building structures, these solutions offer faster, reliable installation through innovative labor saving technologies, using less space than conventional approaches.

Solutions for both indoor and outdoor deployment offer flexibility to use the best available pathways for each building. The solution building blocks include a wide range of terminals, splitters, point-of-entry modules, riser cables, attic and wall fish fiber, hallway fiber and complete indoor living unit fiber kits. This portfolio allows service providers to select the best solution for each building, and OFS can help design building specific solutions and bills of material as a value added service.

FIBER TO THE BUILDING BENEFITS

OFS fiber-to-the-subscriber (FTTx) solutions help to revolutionize the speed of installing fibers; enhance the customer experience; minimize disruption; reduce labor costs; increase subscriber take rates; enable faster time to revenue for service providers; and get Gigabit and higher speeds faster to subscribers.

OPTICAL FIBER BUILDING CHALLENGES AND SOLUTIONS

- Time to revenue: Fast and easy to install pre-terminated solutions can speed installation and reduce labor costs.

- No pathways, requiring labor intensive cut and patch: Compact surface mounted fiber solutions.

- Limited closet space: Smaller enclosures can enable installation of multiple operator connections in a small telecommunications closet.

- Multiple boxes for splicing and splitter connections: Single box pre-terminated solutions can require less space and enable faster provisioning.

- No duct space: Compact surface mounted fiber solutions either inside or on the outside of the building do not require duct.

- Shared infrastructure: Compact cables can support multiple service providers in telecommunication pathways.

- Fiber bends around many corners: Bend-insensitive fiber specified to support bend radius as low as 2.5 mm.

- Disruptive/noisy to tenants: Optical solutions that are virtually invisible can be installed quickly and quietly and preserve the building decor.

- Service disruptions and lost subscribers: Full solution of fiber, cable and connectors from one company, designed to work together. Factory tested to Tier 1 standards.

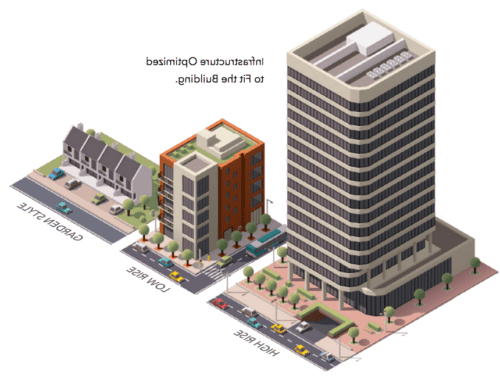

- Multiple building types: Solutions to fit each building type.

PRE-TERMINATED vs. FIELD TERMINATED OPTICAL FIBER

Pre-terminated solutions are increasingly used to install fiber in Multiple Dwelling Unit (MDU) buildings to save time and money in higher labor cost regions. Pre-terminated products with built-in slack management are preferred so installers can neatly manage excess slack and use a single component to support multiple deployment lengths. Nevertheless, field terminated solutions can complement pre-terminated parts of the indoor or outdoor network and, for low labor cost markets, field terminated solutions may be preferred. OFS offers both pre-terminated and field terminated solutions to fit the needs of each service provider.

OPTICAL FIBER SPECIFICATIONS OPTIMIZED TO THE APPLICATION

Installing optical fiber in buildings and homes often requires conforming the fiber around sharp corners. EZ- Bend® Single-Mode Fiber offers outstanding bend performance down to a 2.5 mm radius for the most challenging in-residence and MDU applications. Compatible with the installed base of conventional G.652.D single-mode fibers, the fiber meets and exceeds ITU-T G.657.B3 recommendations. EZ-Bend fiber uses patented, groundbreaking EZ-Bend Optical Technology from OFS to provide three times lower loss at tight bends than competing G.657.B3 products.

Centralized, Distributed and Distributed Cascaded Splitting

As FTTx deployment accelerates globally to meet increasing bandwidth needs, service providers must install optical fiber both to and inside the building for business and residential subscribers. Building types include duplexes, garden style, low rise (less than 10 floors), mid rise (10 to 15 floors), high rise (16 to 40 floors) and skyscrapers (40 floors and above). To provide building Gigabit services, providers must place optical cables in building risers and ducts, install optical fiber in hallways, and then take this fiber deep into the units, connecting to an indoor Optical Network Terminal (ONT). How can providers accomplish this in buildings that can vary widely in design, materials and available pathways?

Splitter Architectures

A typical PON network consists of the Optical Line Terminal (OLT) in a central office, head end or cabinet, connected by a feeder cable to optical splitters, and then to distribution cables downstream in the network. Choosing the right architecture depends upon end-user density, projected subscription rates and distance from the OLT. Splitter placement is important in FTTx design as it can significantly affect plant and electronics costs.

A typical PON network consists of the Optical Line Terminal (OLT) in a central office, head end or cabinet, connected by a feeder cable to optical splitters, and then to distribution cables downstream in the network. Choosing the right architecture depends upon end-user density, projected subscription rates and distance from the OLT. Splitter placement is important in FTTx design as it can significantly affect plant and electronics costs.

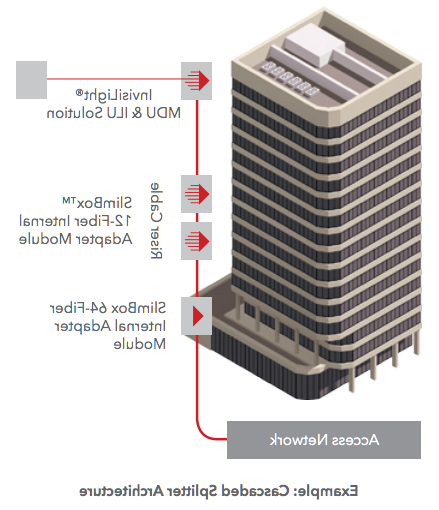

Three common types of splitter architectures are used when deploying FTTx:

- Centralized splitting

- Distributed splitting

- Distributed cascaded splitting

To help meet these needs, the OFS portfolio supports all three splitter architectures, and features a broad range of solutions to meet the requirements of virtually any MDU deployment. For flexibility and regional preferences, these offers include a mix of pre-connectorized, in-field fusion splicing and mechanical connector solutions from which OFS can configure customized designs for each type of building.

Brownfield Outdoor Facade Solution

The Outdoor Facade Solution is used when property owners want to preserve the decor of the building exterior. The compact EZ-Bend Indoor/Outdoor cable is placed vertically on the exterior wall of the residence from an outdoor wall mount box to an indoor SlimBox® unit. The indoor SlimBox can be factory configured with SCA adapters or fanouts for a pre-terminated solution, or for fusion splicing. EZ-Bend jumpers are used for the path to each living unit. Pre-terminated EZ-Bend Jumpers are recommended for faster installation, or a mechanical connector may be used for field termination in the SlimBox Wall Plate. The 80×80 InvisiLight® Module can be used as a “fiber extension” to any location in the living unit. Alternatively, instead of EZ-Bend jumpers, the InvisiLight MDU solution may be placed in the hallway to the living units (not shown).

Brownfield Outdoor Facade Solution

Greenfield Pre-Terminated Solution

TELECOMMUNICATION ROOM

- Compact basement box for a progressive customer activation;

- The basement box (SlimBox 64F Terminal) allows fusion splices for the outside plant cable;

- Ideal for buildings with low penetration rates: One splitter can be installed and the management of the customers is done through the SCA ports. A parking area permits easy connection of new customers;

- Several boxes can be connected for modular expansion. Connections between multiple SlimBoxes are possible through access openings between them.

RISER BACKBONE

- SCA pre-terminated cables for quick plug and play installation;

- EZ-Bend patch cords directly from the apartment unit may be used for small buildings.

HORIZONTAL DEPLOYMENT

- Direct deployment from the telecommunication closet to the apartment unit;

- Ideal for Greenfield installation;

- The EZ-Bend jumper is connected to an adapter installed in the SlimBox Wall Plate (inside the living unit).

INSIDE THE LIVING UNIT

- An SCA mechanical connector can be used to terminate the EZ-Bend Jumper inside the living unit;

- The InvisiLight ILU Solution is a complementary product used to extend the fiber inside the apartment.

Greenfield Fusion Spliced or Field Terminated Solution

TELECOMMUNICATION ROOM

- Compact basement box for a progressive customer activation (parking up to 48 connectors in the SlimBox 64F Terminal);

- The basement box (SlimBox 64F Terminal) allows fusion splices for the outside plant cable and the internal cables (up to 96 fusion splices – 8 splice trays with 12 splices in each one);

- Ideal for buildings with low penetration rate: One splitter can be installed with management of the customers done through the SCA ports. A parking area permits easy connection of new customers;

- Several boxes can be connected for modular expansion. Connections between SlimBoxes are possible through access openings between them.

RISER BACKBONE

- ACCUMAX® cables may be used for quick and easy installation:

- SCA pre-terminated pigtails are used for fusion splicing inside the basement and floor boxes.

HORIZONTAL DEPLOYMENT

- Direct deployment from the telecommunication closet to the apartment unit through EZ-Bend cable (ruggedized 3.0 or 4.8 mm);

- The horizontal cable is fusion spliced or field terminated with a mechanical connector in the SlimBox 12F Terminal (floor distribution box) and in the SlimBox Wall Plate (inside the living unit).

INSIDE THE LIVING UNIT

- An SCA mechanical connector can be used to terminate the EZ-Bend Jumper inside the living unit or a pre-terminated pigtail can be used;

- The InvisiLight ILU Solution is a complementary product used to extend the fiber inside the apartment.

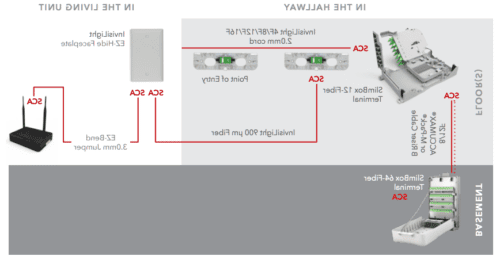

Brownfield Pre-Terminated Solution

Brownfield Pre-Terminated Solution

TELECOMMUNICATION ROOM

- Compact basement box for progressive customer activation;

- The basement box (SlimBox™ 64F Terminal) allows fusion splices to the outside plant cable;

- Ideal for buildings with low penetration rate: One splitter can be installed with management of the customers done through the SCA ports. A parking area permits easy connection of new customers;

- Boxes can be added for modular expansion. Connections between SlimBox units are easily made using jumpers through multiple ports designed into the box.

RISER BACKBONE

- SCA pre-terminated cables for quick plug and play installation:

- It is possible to place InvisiLight 2.0 mm 12-Fiber multifiber cord directly from the basement box and down hallways in small or garden style buildings.

HORIZONTAL DEPLOYMENT

- The InvisiLight MDU Point of Entry (POE) Module offers a discrete solution using field termination inside the module;

- Virtually invisible installation using the InvisiLight 12F Pre-terminated 2.0 mm cord.

INSIDE THE LIVING UNIT

- InvisiLight ILU Solution is complementary and connects to the InvisiLight MDU installation;

- InvisiLight ILU Solution is installed with the same tools and procedures as the InvisiLight MDU Solution

This 64-page guide with illustrations and part specifications will help in selecting the right fiber optic cables and accessories to reduce both the first and life cycle costs of fiber deployments to business customers inside buildings.